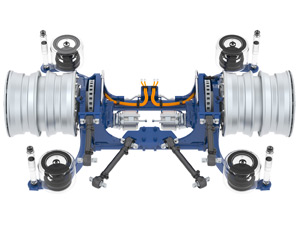

Ziehl-Abegg, the electric motor manufacturer, is revolutionising the architecture of commercial vehicles: with independent suspension in-wheel hub drives (ZAwheel) and a modular construction kit for the spring system – conventional pneumatic or hydro-pneumatic. Opening up a totally new range of options for interior design, low-floor use and weight class. It also provides a totally new driving experience and, thanks to the refined suspension kinematics, a consistent reduction in tyre wear. This technology has attracted the interest of several commercial vehicle manufacturers.

The first double-decker buses to have been converted from diesel to electric with ZAwheel are also being premiered at IAA Commercial Vehicles. The intention now is for several hundred conventional double-decker buses to be converted to electric vehicles.

In addition to its application for city buses, the independent suspension has also been developed for the whole of the commercial vehicle sector. The current axle drive module from Ziehl-Abegg has two in-wheel hub motors and significantly extends the usable space above the drive axle compared with conventional axle systems. “Our ZAwheel in-wheel hub drive enables us to make a significant reduction in the amount of space required if we use independent suspension", explains Ralf Arnold, Managing Director of Ziehl-Abegg Automotive. This subsequently also considerably increases the utilisable space which in turn brings benefits across the board for commercial vehicle development.

Whilst the axle drive module is already on the market, Ziehl-Abegg sees independent suspension as a future concept. "We are talking to a number of commercial vehicle manufacturers who are very interested in independent suspension," says Arnold. Traditionally, these manufacturers rely on pneumatic systems for braking and suspension. In addition to this solution, Ziehl-Abegg is offering yet another step in the development process for a range of totally new concepts in terms of installation space: a hydraulic braking system combined with hydro-pneumatic suspension. A modular system has been developed for this purpose, enabling all the available technologies from the field of pneumatics, hydraulics and electrics to be combined in order meet the client’s wishes as far as possible.

A ‘quick fire’ solution for the integration of a purely hydraulic system will not be possible as this will require a complete revamp of the vehicle architecture. For example, the front axle would also have to be fitted with hydro-pneumatic suspension. When the concept is applied, space is created for the battery packs in the vehicle substructure, shifting the centre of gravity downwards. “This makes it possible to design lightweight, electrically-powered commercial vehicles and to save energy,” enthuses motor expert Arnold. “I’m curious to see which commercial vehicle manufacturer will be the first to opt for this future concept.”

On journeys using hydro-pneumatic independent suspension, the rolling motion on bends is completely eliminated and that’s without the use of a mechanical anti roll bar. The chassis can also be raised and lowered completely, allowing for ultra-low-floor design vehicles. “Independent suspension is the logical further development of our ZAwheel", emphasises Arnold. “Because the significant saving in space can only be achieved with genuine in-wheel hubs.” This is shown by the example of city buses: “Thanks to the width of the aisle, prams or wheelchairs can use the whole length of the bus”, underlines Arnold. Up to now, space for prams and wheelchairs has only been available in the boarding areas in the middle of the buses.

New sightseeing buses from the Spanish manufacturer UNVI fitted with ZAwheel

The Spanish sightseeing bus manufacturer UNVI has been offering new vehicles with the silent, in-wheel hub drive, ZAwheel, for almost a year now. The first examples of the double-decker buses are already operating in Paris and Amsterdam and will soon also be seen on the streets of London. Other cities will follow. Incidentally, the French national football team held its triumphal procession through Paris in a UNVI bus: silently powered by in-wheel hub drives from Ziehl-Abegg.

Hundreds of diesel double-decker buses fitted with electric drives from Ziehl-Abegg

ZAwheel is not only available for new vehicles but for retrofitting as well. Numerous city tour buses in Berlin are now being converted to electric vehicles. Double-decker buses used by tourists from all over the world for their tours of the capital. The buses were initially operated on the scheduled routes of the Berliner Verkehrsbetriebe (BVG) [Berlin public transport companies] and subsequently converted for their second career in the tourism industry. However, with their outdated diesel engines, these double-deckers are not fitted modern drives. Hundreds of buses are now being converted to electric vehicles: With in-wheel hub drives from Ziehl-Abegg. Delivery will start in 2019.

The engine manufacturer Ziehl-Abegg designs, develops and manufactures the electric drive axle as a plug-and-play conversion kit for diesel-powered vehicles. The electric drives and power electronics are integrated into the wheel hubs, providing for a compact design that is especially suitable for low-floor buses. The traction battery is designed for this purpose and the size adapted according to the range requirement. After the conversion, the battery is housed in, amongst other places, the space previously occupied by the diesel engine.

Über Ziehl-Abegg

Ziehl-Abegg (Kuenzelsau, Germany) is one of the leading global companies in the field of ventilation, control and drive technology. Back in the Fifties, Ziehl-Abegg established the basis for modern fan drives: external rotor motors which even today are still seen as state-of-the-art worldwide. Another area of business is electric motors which provide the power, for example, for elevators, medical applications (computer tomography equipment) or deep-sea underwater vehicles. The theme of electro-mobility for motor vehicles was established as part of the Ziehl-Abegg Automotive Team in 2012.

The high-tech company has an impressive innovative capability. Ziehl-Abegg employs 2,200 personnel in its production plants in Southern Germany. The company has a global workforce of 3,900 spread between 16 production plants, 28 companies and 108 sales locations. The products, approx. 30,000 in all, are sold in more than 100 countries. Turnover in 2017 totalled 540 million euros, with exports accounting for three quarters of the figure.

Emil Ziehl founded the company in Berlin in 1910 as a manufacturer of electric motors. After the Second World War the company’s headquarters were relocated to Southern Germany. Ziehl-Abegg SE is not a listed company but instead is family-owned. For more information go to www.Ziehl-Abegg.com.

Türkçe karakter kullanılmayan ve büyük harflerle yazılmış yorumlar onaylanmamaktadır.